Zelf een zeef maken

Een zeef kun je vrij gemakkelijk zelf maken. De materialen zijn gemakkelijk bij de bouwmarkt / doe-het-zelf zaak te vinden. Iets moeilijker is het vinden van de juiste gaas. Deze moet niet enkel de juiste maaswijdte hebben, maar ook stevig zijn en bij voorkeur roestvrij. Gaas gemaakt uit een dunnere gaasdraad 'snijdt' beter door zand bij het schudden, en werkt comfortabeler.

Kies een maaswijdte in functie van de grootte van de fossielen die je wil vinden en de aard van het materiaal waarin je zoekt. Is de maaswijdte te groot, verlies je een deel van de fossielen, kies je ze te klein, dan kan je problemen krijgen dat het zand niet of moeilijk door de zeef kan. Je kan ook meerdere zeven met uiteenlopende maaswijdtes maken, of inlegstukken die je in een zeef kan leggen om met een kleinere maaswijdte te zeven.

Een goede standaard maaswijdte voor veelzijdig gebruik is 5 mm.

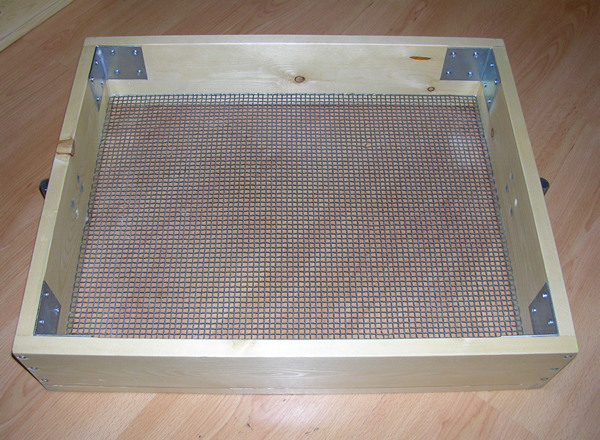

Voorbeeld van een eigenbouw zeef

Volle zeven kunnen soms best zwaar zijn. Je kunt daarvoor een pootconstructie maken waar de zeef op rust. Door de poten in het zand te steken kun je het geheel gemakkelijk heen en weer schudden om te zeven. In het voorbeeld is gebruik gemaakt van standaard betonijzer. Aan de poten zijn uitsteeksels gelast, zodat ze op de aan de zeef passen. Deze poten zijn nergens te koop, dus je zult ze zelf moeten (laten) lassen. Het betonijzer dat ik gebruik is 1,75 meter lang. Het is belangrijk dat de zeef vlot op de poten gezet kan worden en er weer af kan gehaald worden. Je moet immers de zeef kunnen leeggieten na het doorzoeken. Een kleinere zeef weegt minder en kan je gewoon voorzien van handvaten.

Let bij de bouw van je zeef op de volgende zaken:

- Zet het houten frame stevig in elkaar. Gebruik bij voorkeur (hout)lijm én schroeven. Voor extra stevigheid kun je hoekbeugels gebruiken.

- Maak je zeef niet te groot. Een volle zeef kan best zwaar zijn.

- Voor de duurzaamheid van de zeef kun je het beste roestvrijstalen (RVS) hoekbeugels en schroeven gebruiken. Vooral zout water zorgt voor roest!

- Gebruik watervaste (hout)lijm

- Zet het gaas goed vast. Je kunt het best vastklemmen door er een extra latje overheen te schroeven. Dit voorkomt dat het gaas snel los kan gaan van het frame van je zeef.

- Zet de zeef goed in de lak of verf. Als de zeef zich volzuigt met water wordt deze onnodig extra zwaar.

Het gebruik van hoekbeugels is noodzakelijk voor de stevigheid van de zeef

Een mogelijke manier om poot en houder te ontwerpen

Feedback

Doneer

Wij zijn geheel afhankelijk van donaties. Daarom vragen wij onze gebruikers ons te helpen.